Explaining Ivy Bridge’s Surprisingly High Temperatures

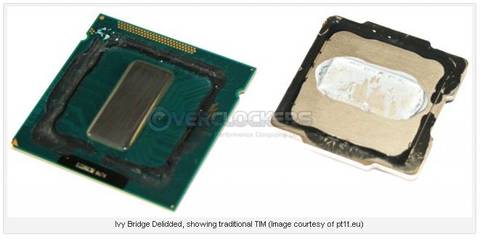

For those eagerly reading the reviews of Intel’s brand new Ivy Bridge CPUs, the successors to Sandy Bridge, would have been shocked and dismayed at the high running temperatures those reviews reported when they were overclocked. It appears that the problem isn’t to do with the higher heat density of the physically smaller core, but due to the way that the Integrated Heat Spreader (IHS) is attached to the CPU die. With SB, fluxless solder was used, but with IB, just thermal paste which might be to help protect the core from physically breaking under stress, but this is by no means clear.

When one compares the thermal conductivity for the two materials, the difference becomes clear: solder has around 80 W/mK thermal conductivity, while paste is around 5 W/mK: in other words, they are in a different league. Now, while an SB CPU is in contact with its CPU cooler with a 5 W/mK paste, IB now has two such barriers, lowering heat conductivity significantly. The IHS then effectively becomes a heat barrier rather than a heat conductor, which gives us a hot-running CPU. Intel has switched between the two CPU-IHS interface methods over the years and each time thermal paste was used, the chips ran hot. Moral of the story: for enthusiasts that like to overclock, keep your Sandy Bridge. It doesn’t appear that Intel has designed IB with enthusiasts in mind. Perhaps a later revision of IB or the next gen Haswell will fix this, or perhaps the actual shipping CPUs available from the 29th will use a solder IHS connection?

How does TIM paste generally compare with fluxless solder for conducting heat? Heat conductivity can be measured in watts per meter Kelvin. To be technically exact, we would need to know exactly what Intel is using for TIM paste/solder. When I went to Intel and asked, their polite answer may not surprise you “Secret sauce”!

Comments are closed.